|

Ningbo Dongsheng Strong Magnet Material Co.,Ltd.

|

High Power Irregular Neodymium Magnets

| Price: | 0.1~100.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1) High quality consistency

2) Shape can be customer required

3) SST: 48/72 hours

4) Coating NI ZN Black epoxy

SinteredIrregular NdFeB Magnets for Generator

Description | Neodymium (NdFeB) Magnet | ||

Material | Sintered Neodymium-Iron-Boron | ||

Working Temperature | Grade | Max. Operating TemD3mm neodymium small disc magnet perature | |

N35-N52 | 80°C (176°F) | ||

33M- 48M | 100°C (212°F) | ||

33H-48H | 120°C (248°F) | ||

30SH-45SH | 150°C (302°F) | ||

30UH-40UH | 180°C (356°F) | ||

28EH-38EH | 200°C (392°F) | ||

28AH-35AH | 230°C (428°F) | ||

Magnet Shape | Disc, Cylinder, Block, Bar, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more. Customized shapes for Neodymium(NdFeB) Magnet are available. | ||

Magnet Coating | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Chrome and so on. | ||

Directions of Magnetization | Axial, thickness, radial, diameter,Multi-pole oriented | ||

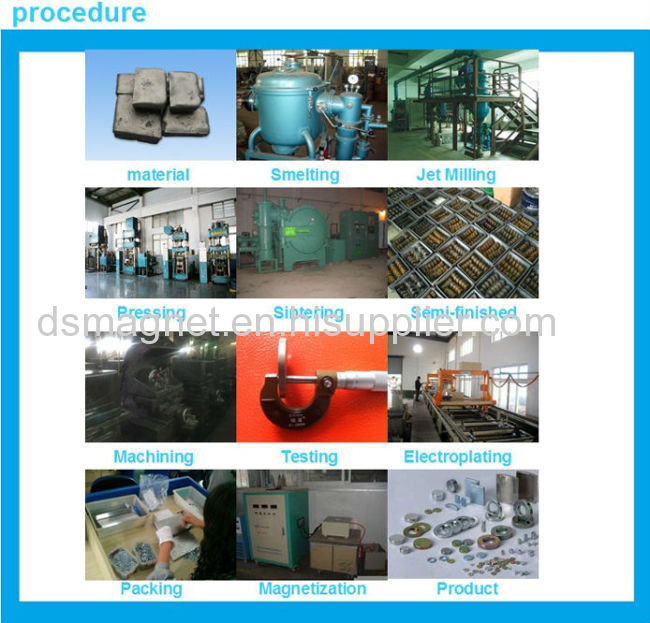

Produts Tech: | Raw materials-Burdening-Melting-Crushing-Milling-Pressing- Vacuum sintering-Maching-Plating -Inspection-Packing | ||

Environment and recycle friendly | Meet the environment standard of RoHS,Reach issued by EU. Electroplating uses chemical-plating processing technology without lead and chromium. | ||

Technology Advantage | Depending on advanced R&D center, Quality control team and professional machining technicians, we can surpass our competitors in the stability of quality and superiority of property. | ||

Delivery Advantage | The lead time must be 3-5 days quicker than industry average because of more flexible machine process control. | ||

Price Advantage | The price is 5-10% cheaper than industry average because of an excellent and efficient management system. | ||

Application | Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, VCMs in hard disk drives, printer, switchboard, loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, common daily use, and so on | ||

Physical Characteristic Of NeFeB Magnet :

| Grade | Br mT (kGs) | Hcb kA/m (kOe) | Hcj kA/m (kOe) | (BH)max kJ/m3 | Working Temperature (Tw) |

| (MGOe) | |||||

| N33 | 1130-1170(11.3-11.7) | ≥836 ( ≥ 10.5) | ≥955( ≥ 12) | 247-271(31-34) | 80 ℃ |

| N35 | 1170-1220(11.7-12.2) | ≥868( ≥ 10.9) | ≥955( ≥ 12) | 263-287(33-36) | |

| N38 | 1220-1250(12.2-12.5) | ≥899( ≥ 11.3) | ≥ 955( ≥ 12) | 287-310(36-39) | |

| N40 | 1250-1280(12.5-12.8) | ≥907( ≥ 11.4) | ≥955 ( ≥ 12) | 302-326(38-41) | |

| N42 | 1280-1320(12.8-13.2) | ≥915( ≥ 11.5) | ≥955( ≥ 12) | 318-342(40-43) | |

| N45 | 1320-1380(13.2-13.8) | ≥923( ≥ 11.6) | ≥955 ( ≥ 12) | 342-366(43-46) | |

| N48 | 1380-1420(13.8-14.2) | ≥923( ≥ 11.6) | ≥876( ≥ 12) | 366-390(46-49) | |

| N50 | 1400-1450(14.0-14.5) | ≥796( ≥ 10.0) | ≥876( ≥ 11) | 382-406(48-51) | 60 ℃ |

| N52 | 1430-1480(14.3-14.8) | ≥796( ≥ 10.0) | ≥876( ≥ 11) | 398-422(50-53) | |

| 30M | 1080-1130(10.8-11.3) | ≥796( ≥ 10.0) | ≥1114 ( ≥ 14) | 223-247(28-31) | 100 ℃ |

| 33M | 1130-1170(11.3-11.7) | ≥836( ≥ 10.5) | ≥1114( ≥ 14) | 247-263(31-33) | |

| 35M | 1170-1220(11.7-12.2) | ≥868( ≥ 10.9) | ≥1114( ≥ 14) | 263-287(33-36) | |

| 38M | 1220-1250(12.2-12.5) | ≥899( ≥ 11.3) | ≥1114( ≥ 14) | 287-310(36-39) | |

| 40M | 1250-1280(12.5-12.8) | ≥923( ≥ 11.6) | ≥1114( ≥ 14) | 302-326(38-41) | |

| 42M | 1280-1320(12.8-13.2) | ≥955( ≥ 12.0) | ≥1114( ≥ 14) | 318-342(40-43) | |

| 45M | 1320-1380(13.2-13.8) | ≥995( ≥ 12.5) | ≥1114 ( ≥ 14) | 342-366(43-46) | |

| 48M | 1360-1430(13.6-14.3) | ≥1027( ≥ 12.9) | ≥1114( ≥ 14) | 366-390(46-49) | |

| 50M | 1400-1450(14.0-14.5) | ≥1033 ( ≥ 13.0) | ≥1114( ≥ 14) | 382-406(48-51) | |

| 30H | 1080-1130(10.8-11.3) | ≥796 ( ≥ 10.0) | ≥1353( ≥ 17) | 223-247(28-31) | 120 ℃ |

| 33H | 1130-1170(11.3-11.7) | ≥836 ( ≥ 10.5) | ≥1353( ≥ 17) | 247-271(31-34) | |

| 35H | 1170-1220(11.7-12.2) | ≥868 ( ≥ 10.9) | ≥1353( ≥ 17) | 263-287(33-36) | |

| 38H | 1220-1250(12.2-12.5) | ≥899 ( ≥ 11.3) | ≥1353 ( ≥ 17) | 287-310(36-39) | |

| 40H | 1250-1280(12.5-12.8) | ≥923( ≥ 11.6) | ≥1353( ≥ 17) | 302-326(38-41) | |

| 42H | 1280-1320(12.8-13.2) | ≥955 ( ≥ 12.0) | ≥1353( ≥ 17) | 318-342(40-43) | |

| 45H | 1300-1360(13-13.6) | ≥963( ≥ 12.1) | ≥1353 ( ≥ 17) | 326-358(43-46) | |

| 48H | 1370-1430(13.7-14.3) | ≥995( ≥ 12.5) | ≥1353( ≥ 17) | 366-390(46-49) | |

| 30SH | 1080-1130(10.8-11.3) | ≥804( ≥ 10.1) | ≥1592( ≥ 20) | 223-247(28-31) | 150 ℃ |

| 33SH | 1130-1170(11.3-11.7) | ≥844( ≥ 10.6) | ≥1592( ≥ 20) | 247-271(31-34) | |

| 35SH | 1170-1220(11.7-12.2) | ≥876 ( ≥ 11.0) | ≥1592( ≥ 20) | 263-287(33-36) | |

| 38SH | 1220-1250(12.2-12.5) | ≥907( ≥ 11.4) | ≥1592( ≥ 20) | 287-310(36-39) | |

| 40SH | 1240-1280(12.5-12.8) | ≥939( ≥ 11.8) | ≥1592( ≥ 20) | 302-326(38-41) | |

| 42SH | 1280-1320(12.8-13.2) | ≥987 ( ≥ 12.4) | ≥1592 ( ≥ 20) | 318-342(40-43) | |

| 45SH | 1320-1380(13.2-13.8) | ≥1003 ( ≥ 12.6) | ≥1592( ≥ 20) | 342-366(43-46) | |

| 28UH | 1020-1080(10.2-10.8) | ≥764 ( ≥ 9.6) | ≥1990 ( ≥ 25) | 207-231(26-29) | 180 ℃ |

| 30UH | 1080-1130(10.8-11.3) | ≥812( ≥ 10.2) | ≥1990( ≥ 25) | 223-247(28-31) | |

| 33UH | 1130-1170(11.3-11.7) | ≥852( ≥ 10.7) | ≥1990 ( ≥ 25) | 247-271(31-34) | |

| 35UH | 1180-1220(11.8-12.2) | ≥860 ( ≥ 10.8) | ≥1990( ≥ 25) | 263-287(33-36) | |

| 38UH | 1220-1250(12.2-12.5) | ≥876 ( ≥ 11.0) | ≥1990( ≥ 25) | 287-310(36-39) | |

| 40UH | 1240-1280(12.5-12.8) | ≥899( ≥ 11.3) | ≥1990( ≥ 25) | 302-326(38-41) | |

| 28EH | 1040-1090(10.4-10.9) | ≥780( ≥ 9.8) | ≥2388( ≥ 30) | 207-231(26-29) | 200 ℃ |

| 30EH | 1080-1130(10.8-11.3) | ≥812 ( ≥ 10.2) | ≥2388 ( ≥ 30) | 223-247(28-31) | |

| 33EH | 1130-1170(11.3-11.7) | ≥836 ( ≥ 10.5) | ≥2388 ( ≥ 30) | 247-271(31-34) | |

| 35EH | 1170-1220(11.7-12.2) | ≥876 ( ≥ 11.0) | ≥2388( ≥ 30) | 263-287(33-36) | |

| 38EH | 1220-1250(12.2-12.5) | ≥899( ≥ 11.3) | ≥2388( ≥ 30) | 287-310(36-39) |

Our product

The Production Process :