|

Ningbo Dongsheng Strong Magnet Material Co.,Ltd.

|

Sintered Ndfeb Magnet Block

| Price: | 0.01~100.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Grade can be N35,N35H, N38,N40,N50 N52

Shape can be customer require

Coating can be Ni-Cu-Ni, Zn, Blac

Description

Material: NdFeB, Grade 33MGOe to 52MGOe

Dimensions: Almost any size and shape

Tolerance: +/-0.1mm

Plating/Coating: Can be NiCuNi, Zn, Epoxy, Gold and Silver etc.

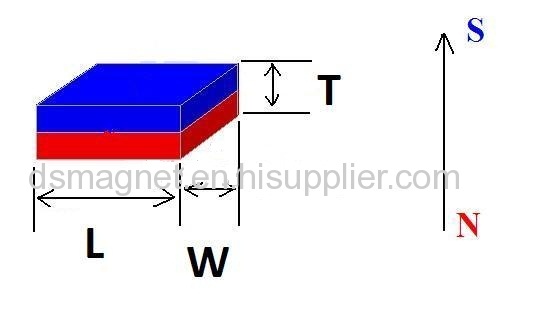

Magnetization Direction: Axially magnetized

Weight:

Surface Gauss:

Max. Working Temperature: 80ºC-200ºC

Brmax: 14,800 Gauss

BHmax: 52MGOe

Neodymium(NdFeB) magnets are made from Neodymium, iron, boron(Nd2Fe14B) and few other rare earth elements under four main production processes-raw material melting/powder making/mould pressing/sintering-to become the semi-finished products that will finally be machined and coated to be the finished parts. The main characteristics: 1)higher remanence(Br); 2)higher Coercivity(Hci) and energy product(BH); 3)lower Curie temperature(Tc). The main Applications: wind generators, DC motors, servo motors, air conditioners, medical equipment, VCM, mobile phones, speakers and magnetic holding and seperation systems etc.

NdFeB Magnet properties

| Magnet Type | Remanence(Br) | HcB | HcJ | (B-H)max | Max.Temp. | ||||

| (KGs) | (mT) | (Koe) | (KA/m) | (Koe) | (KA/m) | (MGOe) | (KJ/m3) | °C | |

| N35 | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥12 | ≥955 | 33-36 | 263-287 | 80°C |

| N38 | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥12 | ≥955 | 36-39 | 287-310 | 80°C |

| N40 | 12.5-12.8 | 1250-1280 | ≥11.4 | ≥907 | ≥12 | ≥955 | 38-41 | 302-326 | 80°C |

| N42 | 12.8-13.2 | 1280-1320 | ≥11.5 | ≥915 | ≥12 | ≥955 | 40-43 | 318-342 | 80°C |

| N45 | 13.2-13.8 | 1320-1380 | ≥11.6 | ≥923 | ≥12 | ≥955 | 43-46 | 342-366 | 80°C |

| N48 | 13.8-14.2 | 1380-1420 | ≥10.5 | ≥836 | ≥12 | ≥955 | 46-49 | 366-390 | 80°C |

| N50 | 14.0-14.5 | 1400-1450 | ≥10.0 | ≥796 | ≥11 | ≥876 | 48-51 | 382-406 | 60°C |

| N52 | 14.3-14.8 | 1430-1480 | ≥10.0 | ≥796 | ≥11 | ≥876 | 50-53 | 398-422 | 60°C |

| 33M | 11.3-11.7 | 1130-1170 | ≥10.5 | ≥836 | ≥14 | ≥1114 | 31-33 | 247-263 | 100°C |

| 35M | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥14 | ≥1114 | 33-36 | 263-287 | 100°C |

| 38M | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥14 | ≥1114 | 36-39 | 287-310 | 100°C |

| 40M | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥14 | ≥1114 | 38-41 | 302-326 | 100°C |

| 42M | 12.8-13.2 | 1280-1320 | ≥12.0 | ≥955 | ≥14 | ≥1114 | 40-43 | 318-342 | 100°C |

| 45M | 13.2-13.8 | 1320-1380 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 43-46 | 342-366 | 100°C |

| 48M | 13.6-14.3 | 1360-1430 | ≥12.9 | ≥1027 | ≥14 | ≥1114 | 46-49 | 366-390 | 100°C |

| 50M | 14.0-14.5 | 1400-1450 | ≥13.0 | ≥1033 | ≥14 | ≥1114 | 48-51 | 382-406 | 100°C |

| 35H | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 33-36 | 263-287 | 120°C |

| 38H | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 36-39 | 287-310 | 120°C |

| 40H | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 38-41 | 302-326 | 120°C |

| 42H | 12.8-13.2 | 1280-1320 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 40-43 | 318-342 | 120°C |

| 45H | 13.2-13.6 | 1320-1360 | ≥12.1 | ≥963 | ≥17 | ≥1353 | 43-46 | 342-366 | 120°C |

| 48H | 13.7-14.3 | 1370-1430 | ≥12.5 | ≥995 | ≥17 | ≥1353 | 46-49 | 366-390 | 120°C |

| 35SH | 11.7-12.2 | 1170-1220 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 33-36 | 263-287 | 150°C |

| 38SH | 12.2-12.5 | 1220-1250 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 36-39 | 287-310 | 150°C |

| 40SH | 12.5-12.8 | 1250-1280 | ≥11.8 | ≥939 | ≥20 | ≥1592 | 38-41 | 302-326 | 150°C |

| 42SH | 12.8-13.2 | 1280-1320 | ≥12.4 | ≥987 | ≥20 | ≥1592 | 40-43 | 318-342 | 150°C |

| 45SH | 13.2-13.8 | 1320-1380 | ≥12.6 | ≥1003 | ≥20 | ≥1592 | 43-46 | 342-366 | 150°C |

| 28UH | 10.2-10.8 | 1020-1080 | ≥9.6 | ≥764 | ≥25 | ≥1990 | 26-29 | 207-231 | 180°C |

| 30UH | 10.8-11.3 | 1080-1130 | ≥10.2 | ≥812 | ≥25 | ≥1990 | 28-31 | 223-247 | 180°C |

| 33UH | 11.3-11.7 | 1130-1170 | ≥10.7 | ≥852 | ≥25 | ≥1990 | 31-34 | 247-271 | 180°C |

| 35UH | 11.8-12.2 | 1180-1220 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 33-36 | 263-287 | 180°C |

| 38UH | 12.2-12.5 | 1220-1250 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 36-39 | 287-310 | 180°C |

| 40UH | 12.5-12.8 | 1250-1280 | ≥11.3 | ≥899 | ≥25 | ≥1990 | 38-41 | 302-326 | 180°C |

| 28EH | 10.4-10.9 | 1040-1090 | ≥9.8 | ≥780 | ≥30 | ≥2388 | 26-29 | 207-231 | 200°C |

| 30EH | 10.8-11.3 | 1080-1130 | ≥10.2 | ≥812 | ≥30 | ≥2388 | 28-31 | 223-247 | 200°C |

| 33EH | 11.3-11.7 | 1130-1170 | ≥10.5 | ≥836 | ≥30 | ≥2388 | 31-34 | 247-271 | 200°C |

| 35EH | 11.7-12.2 | 1170-1220 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 33-36 | 263-287 | 200°C |

| 38EH | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 36-39 | 287-310 | 200°C |

| 28AH | 10.4-10.9 | 1040-1090 | ≥9.9 | ≥787 | ≥33 | ≥2642 | 26-29 | 207-231 | 230°C |

| 30AH | 10.8-11.3 | 1080-1130 | ≥10.3 | ≥819 | ≥33 | ≥2642 | 28-31 | 223-247 | 230°C |

| 33AH | 11.3-11.7 | 1130-1170 | ≥10.6 | ≥843 | ≥33 | ≥2642 | 31-34 | 247-271 | 230°C |

Magnetization direction

Our products

PlatingCharacteristics

| Plating Type | OverallThickness | Salt SprayTest | Pressure CookerTest |

| NiCuNi (Nickel Copper Nickel) | 15-21 μm | 24 hours | 48 hours |

| NiCu + Black Nickel | 15-21 μm | 24 hours | 48 hours |

| NiCuNi + Epoxy | 20-28 μm | 48 hours | 72 hours |

| NiCuNi + Gold | 16-23 μm | 36 hours | 72 hours |

| NiCuNi + Silver | 16-23 μm | 24 hours | 48 hours |

| Zinc | 7-15 μm | 12 hours | 24 hours |

Quick Introduction on How to Send an Inquiry:

(1) Grade

(2) Size

(3) Magnetization Direction

(4) Surface Coating

(5) Quantity

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Block Sintered Ndfeb Magnet

Sintered Ndfeb Magnet

Magnet Ndfeb Sintered

Sintered Ndfeb Permanent Magnet

Sintered Ndfeb Magnet Disc

Sintered Ndfeb

More>>